Heat Exchangers Headline News

News and topics about Tada heat exchangers and their spread from Japan throughout the world.

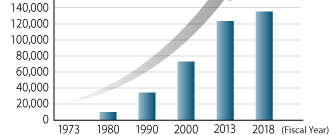

We have an overwhelming share of the Japanese market for coolers used in heavy machinery such as transformers and generators. Tada heat exchangers provide high quality, long service life and high reliability, and are supporting infrastructure around the world.

The high quality of our numerous technologies, cultivated since the founding of the company, is acknowledged worldwide.

- ■Temperature Control Technology with an Error Margin of Only ±0.1°C

- Stable cooling performance keeps cooling water at a constant temperature. Precise temperature adjustment of ±0.1°C is possible for cooling facilities of electromagnet for research.

- ■Operating Control Technology Considering Energy Savings

- We offer operating control systems incorporating energy efficiency, according to variations in the outside environment and load.

- ■Technologies to Stringently Test Performance Under Actual Loads

-

Large-scale facilities fully equipped with equipment to test various heat exchangers under actual loads.

Large-scale facilities fully equipped with equipment to test various heat exchangers under actual loads.

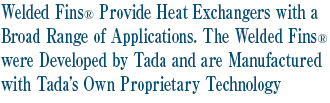

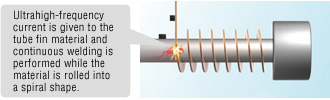

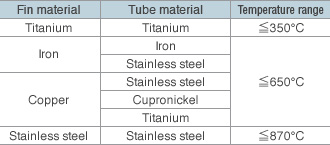

Original manufacturing technologies that enable not only the welding of dissimilar metals, but also welding of copper materials that pose difficulties for resistance welding. Has excellent performance under high-temperature conditions..

■Welded fin production

■Examples of dissimilar metal welding combinations and applicable temperatures

Five surfaces can be processed simultaneously, enabling complicated parts processing to be completed quickly and with high precision.